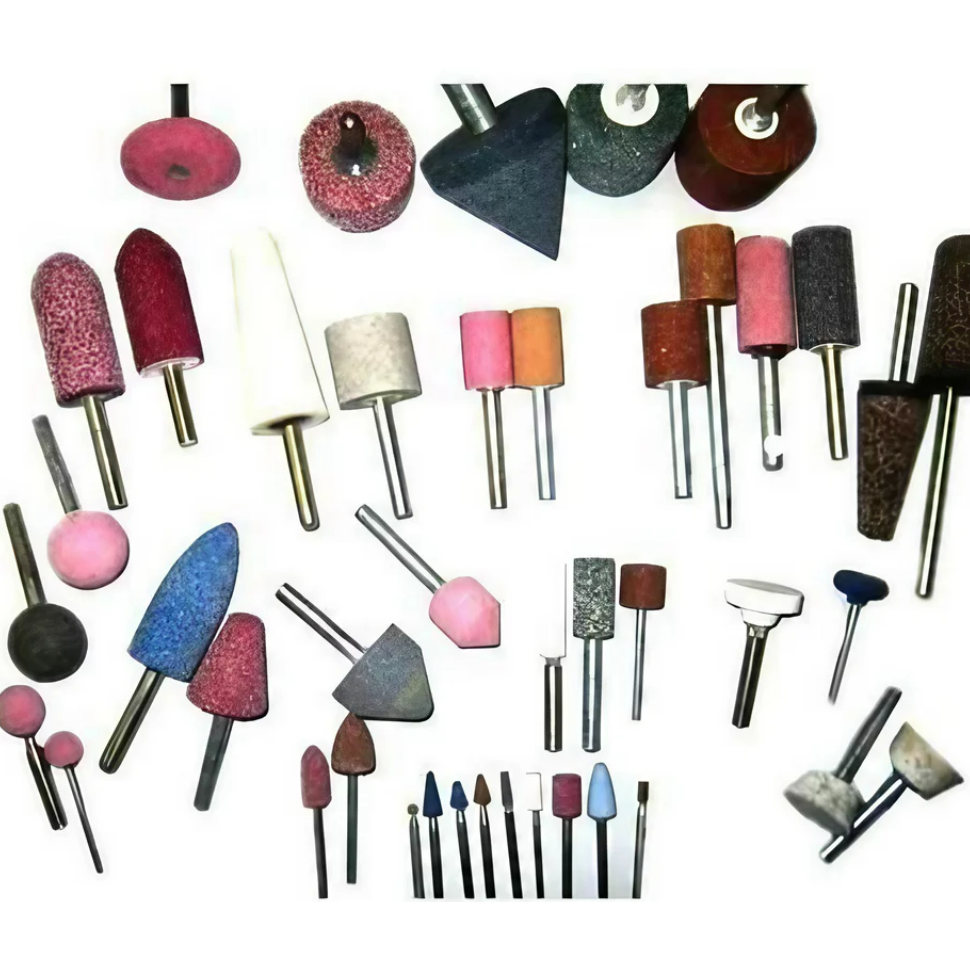

Abrasive mounted points are essential tools used for precision grinding, deburring, polishing, and finishing applications across various industries. Designed with abrasive grains bonded to a spindle or mandrel, these compact tools deliver high accuracy and superior surface quality, especially in hard-to-reach or intricate areas. Their small size, diverse shapes, and versatile performance make them suitable for metalworking, mold making, tool and die production, automotive repairs, and general maintenance tasks. Manufactured using high-quality abrasive materials such as aluminum oxide, silicon carbide, ceramic abrasive, or diamond grains, mounted points are capable of handling a wide range of materials. They efficiently grind stainless steel, alloy steel, cast iron, hardened metals, non-ferrous metals, glass, stone, and even certain composites. Each abrasive type offers unique benefits—aluminum oxide for general-purpose grinding, silicon carbide for non-metallic materials, ceramic abrasives for enhanced durability, and diamond for extremely hard surfaces. A key advantage of abrasive mounted points is their ability to provide precision work. They are available in numerous shapes like cylindrical, conical, ball, wedge, taper, and oval, allowing users to perform detailed finishing tasks in grooves, slots, corners, and curved surfaces. Their rigid bonding and balanced design minimize vibration, ensuring smoother operation and consistent results. These mounted points are compatible with die grinders, rotary tools, and high-speed handpieces, making them easy to use for both professionals and hobbyists. They are ideal for removing weld splatter, blending welded joints, sharpening tools, preparing surfaces for coating, and achieving smooth finishes on machined parts. Additionally, abrasive mounted points are known for their long service life and resistance to wear, reducing the need for frequent replacements. Their reliability and versatility make them an indispensable part of workshop toolkits.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.assoscorp.com/latest-update/abrasive-mounted-point-dealer-in-delhi/6

Abrasive Mounted Point Dealer In Delhi

2025-11-29T04:36:21

Abrasive mounted points are essential tools used for precision grinding, deburring, polishing, and finishing applications across various industries. Designed with abrasive grains bonded to a spindle or mandrel, these compact tools deliver high accuracy and superior surface quality, especially in hard-to-reach or intricate areas. Their small size, diverse shapes, and versatile performance make them suitable for metalworking, mold making, tool and die production, automotive repairs, and general maintenance tasks. Manufactured using high-quality abrasive materials such as aluminum oxide, silicon carbide, ceramic abrasive, or diamond grains, mounted points are capable of handling a wide range of materials. They efficiently grind stainless steel, alloy steel, cast iron, hardened metals, non-ferrous metals, glass, stone, and even certain composites. Each abrasive type offers unique benefits—aluminum oxide for general-purpose grinding, silicon carbide for non-metallic materials, ceramic abrasives for enhanced durability, and diamond for extremely hard surfaces. A key advantage of abrasive mounted points is their ability to provide precision work. They are available in numerous shapes like cylindrical, conical, ball, wedge, taper, and oval, allowing users to perform detailed finishing tasks in grooves, slots, corners, and curved surfaces. Their rigid bonding and balanced design minimize vibration, ensuring smoother operation and consistent results. These mounted points are compatible with die grinders, rotary tools, and high-speed handpieces, making them easy to use for both professionals and hobbyists. They are ideal for removing weld splatter, blending welded joints, sharpening tools, preparing surfaces for coating, and achieving smooth finishes on machined parts. Additionally, abrasive mounted points are known for their long service life and resistance to wear, reducing the need for frequent replacements. Their reliability and versatility make them an indispensable part of workshop toolkits.

2025-11-29T04:36:21

Submit Your Enquiry